In simple terms, eddy current is a type of magnetic loss. When power is lost due to eddy current flow, this condition is called eddy current loss. There are many factors that affect the amount of power loss in eddy current flow, including the thickness of the magnetic material, the frequency of the induced electromotive force, and the density of the magnetic flux.

A DC motor consists of two main components, such as the stator and the rotor. the toroidal core includes the rotor and slots that support the windings and coils. Once the iron core rotates in the magnetic field, a voltage is created in the coil, which creates eddy currents.

The resistance of the material in which the current flows affects how eddy currents develop. For example, when the cross-sectional area of the material is reduced, this results in a reduction in eddy currents. Therefore, the material must be kept thinner to minimize the cross-sectional area and reduce the amount of eddy current flow and losses.

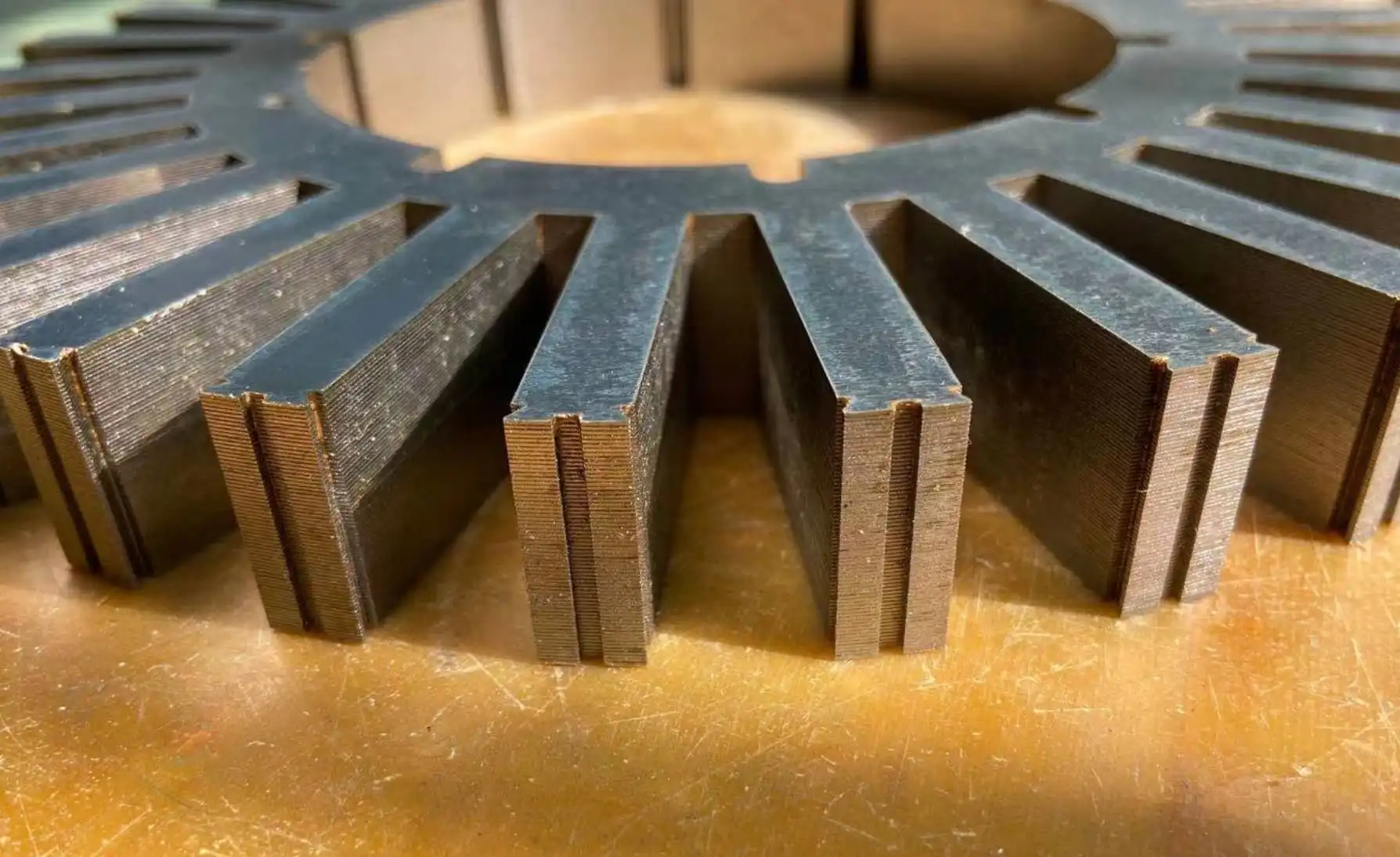

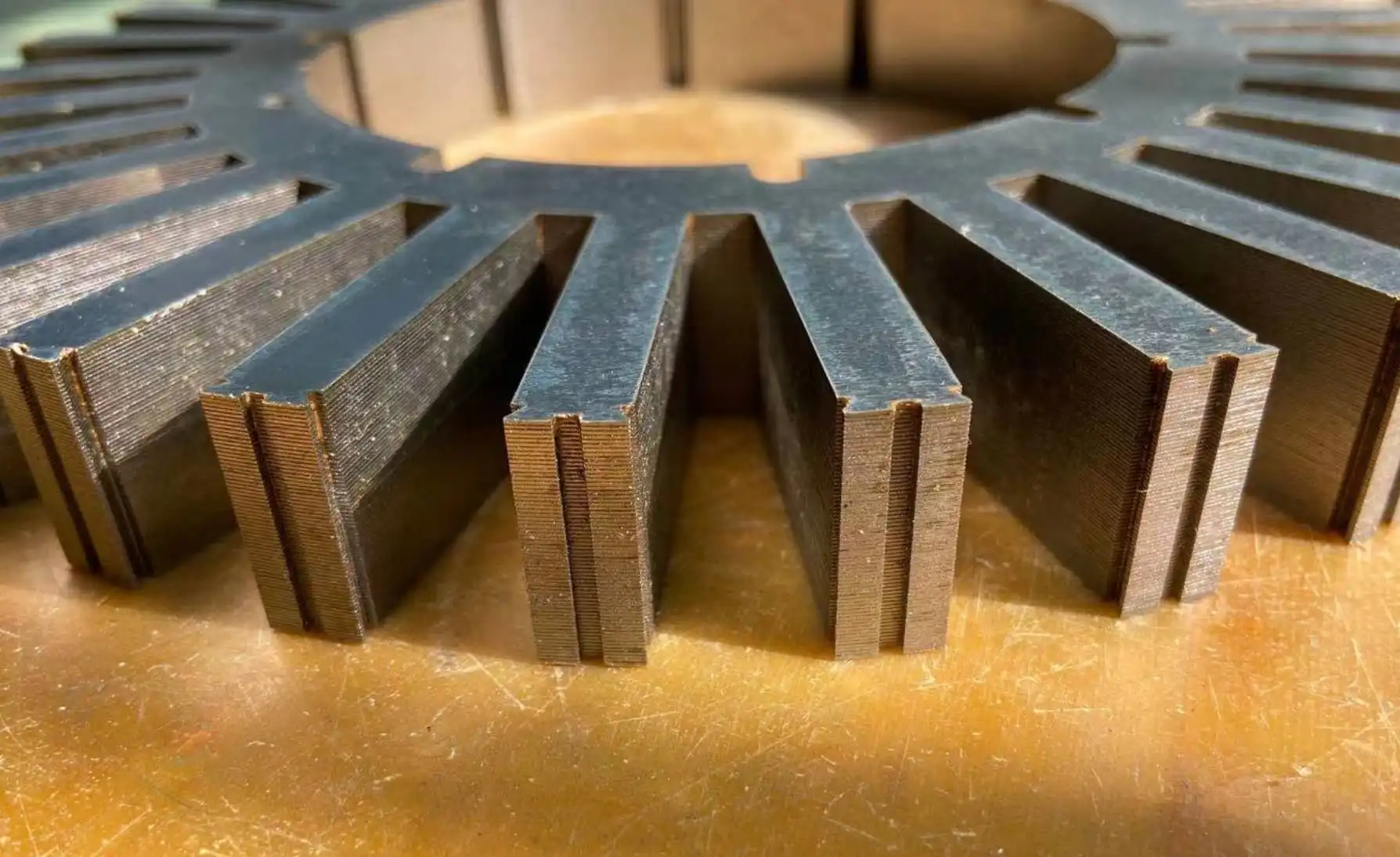

Reducing the amount of eddy currents is why there are several thin iron pieces or pieces of iron that make up the armature core. Not only do these flakes have a strong bulk material, they are also able to create higher electrical resistance. As a result, fewer eddy currents occur, ensuring that less eddy current losses occur. These individual iron sheets, called laminations, carry armatures.

In the case of solid cores, the measured eddy currents are much larger compared to laminated cores. With a lacquer coating, an insulating layer is formed to protect the laminations, as eddy currents cannot bounce from one lamination to the next. Adequate paint coating is the main reason manufacturers ensure that the armature core laminations remain thin - both for cost reasons and for manufacturing purposes. There are modern DC motors that use laminations between 0.1 and 0.5 mm thick.

One of the components of laminated steel sheet is silicon. Silicon protects the iron core of the generator or motor stator as well as the transformer. Once cold rolled and ensured to have a special grain orientation, the steel is used for lamination purposes. This material typically has a thickness of about 0.1/0.2/0.3 mm. the two sides are then insulated and placed on top of each other. Doing this reduces eddy currents as it cannot flow through most of the cross section.

It is not enough for the laminate to have the correct thickness level. Most importantly, the surface must be spotless. Otherwise, foreign matter may form and cause laminar flow failure. Over time, a laminar flow failure can lead to core damage. the laminations are either welded together or glued together. the way you put these together depends on your preferred or desired application. Whether the laminations are loose, bonded or welded, they are preferred over monolithic solid materials to reduce eddy current losses.

Electrical steel laminations can be used to make motor laminations. Manufacturers can use silicon steel, mainly including steel bonded with silicon. This combination is one of the most commonly used materials due to its reliability and strength. the resistance increases with the combination of silicon and steel and the presence of a magnetic field that penetrates the material. Additionally, silicon steel is responsible for minimizing the chance of corrosion. the material also enhances the hysteresis losses of the steel.

Silicon steel is a common choice in a variety of applications where electromagnetic fields are important. These applications include magnetic coils, transformers, electric motors, and electric rotors and stators. By adding silicon to the steel, this increases the speed and efficiency of the steel in generating and maintaining some magnetic fields. With a magnetic core made of steel, any device or device becomes more effective and efficient.