The tool is the core component of the stamping process. It determines the quality of the lamination and the control of burrs is crucial. Manufacturing high-quality molds, high-quality raw materials and precision cutting machines are essential. Our company owns the most advanced slow-moving wire cutting equipment, the cost is high, but it is worth the money.

We have high-speed punching, compound punching, and single-slot punching corresponding molds to meet the needs of different motor stators and rotors. About 90% of our motor laminations are custom made to drawings. During the mold design process, our professional designers will make some constructive suggestions according to the drawings to better satisfy customers.

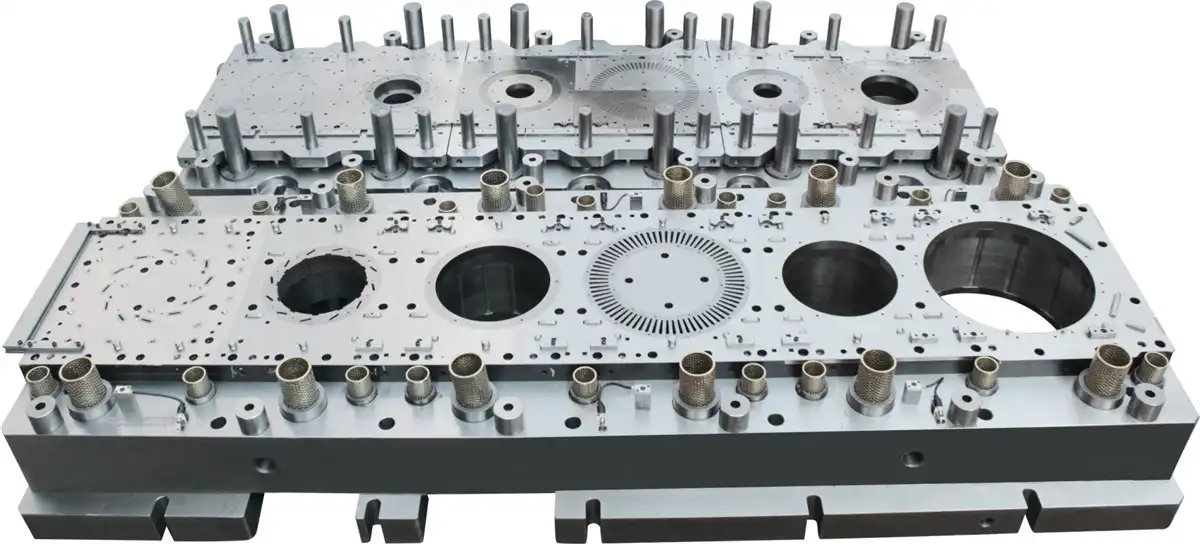

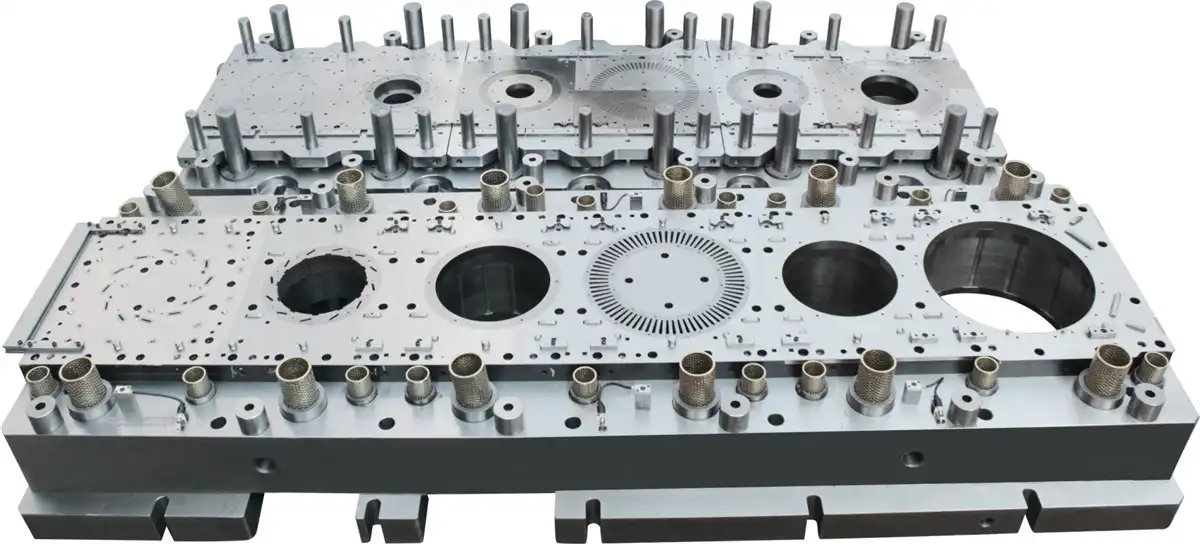

Tool:progressive die

This kind of mold is also called high-speed stamping mold. Different from the compound mold, it can only use the suitable material width for feeding, completing the stamping and self-interlock in the mold directly to form the stator and rotor stack.

There are two types of self-interlock. One is the circular self-interlock point for the small size of motor laminations, which has high technical requirements. The stacks does not need to be pressed twice on the fixture tooling.the other is the rectangular self-interlock point, which requires secondary pressure to ensure fasten.

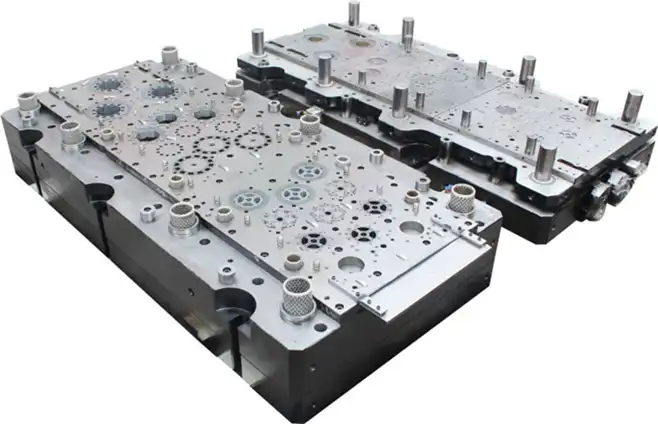

Tool:compound die

Purchase the corresponding silicon steel strip according to the size of the required product, transfer the material to the stamping press, and then form motor laminations,both stator lamination and rotor lamination.

There are two feeding methods,one is to use the wafer punched by other motor lamination, which is inefficient, but can save material costs; the other is continuous feeding of strips, with high efficiency.We will check the wafer stock situation when the customer places an order, and then calculate the best price to make a contract for the motor stator and rotor.

Tool:notch stamping die

Cut the silicon steel sheet to required size, and each piece of them will be individually stamped into the required shape. Single slot stamping is a more suitable way for the stator laminations with larger outer diameter and large amount of samples.