By increasing the efficiency of the motors, electric vehicle can go further without increasing the capacity of existing batteries. The current state of affairs with regard to industrial motors also calls for increased efficiency. A prerequisite for this is the use of low-loss electrical steel combined with high magnetic permeability. Material processing and the bonding techniques used contribute significantly to the performance of our electrical steels in electric motors. The backlack system offers many efficiency and processing advantages over conventional joining technologies.

Electric motors require iron cores, and high-efficiency motors require iron cores made of individually stacked laminations made of electrical steel. But how are these individual laminations optimally bonded in a perfect way? we invite you to find out more.

Backlack - connection technology for perfect laminations!

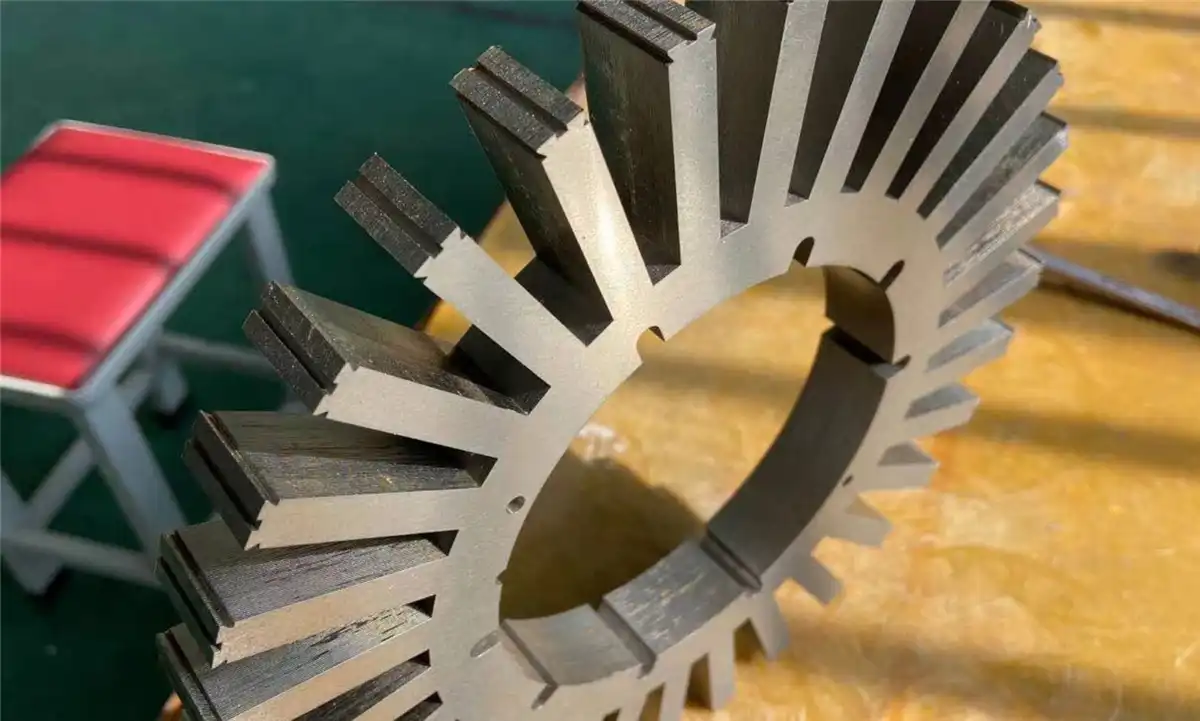

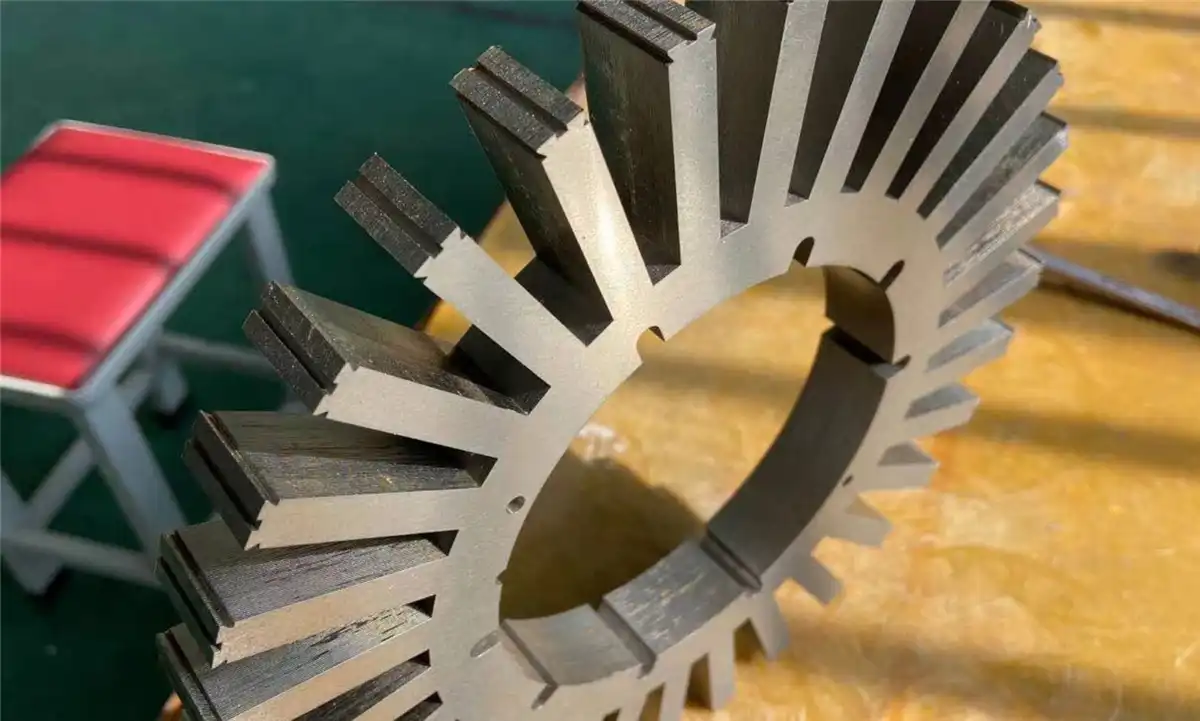

The motor's stator and rotor cores are fabricated using thin laminations that our customers stack together to minimize eddy current losses.