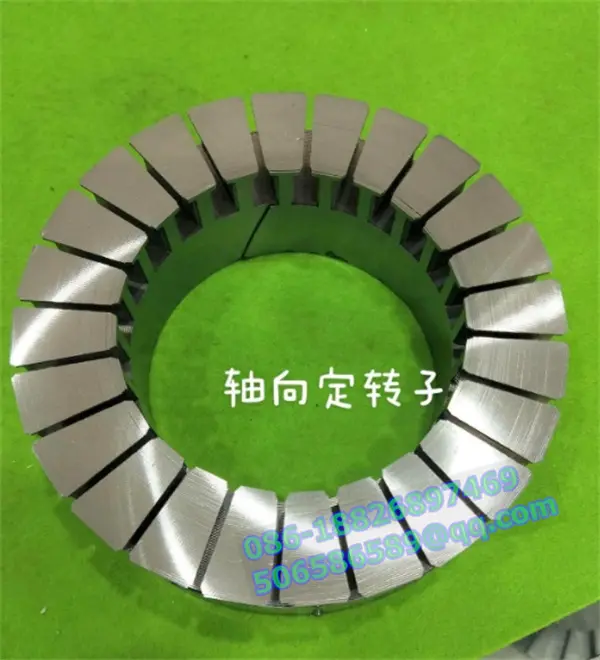

The working process of the disc motor (axial flux motor) stamping and punching coiler usually includes the following steps:

1. Preparation work

Before starting operation, the punching and punching coiler needs to be prepared. This includes checking the condition and safety of equipment and confirming the correct position and condition of punches and coilers.

2. Stamping and punching

In the stamping and punching stage, the disc motor drives the punch to perform stamping and punching operations by controlling the size and direction of the current. Punch punches are usually made of hard material with a specific shape and size and are used to create the desired hole or shape in the workpiece.

3. Coiling material

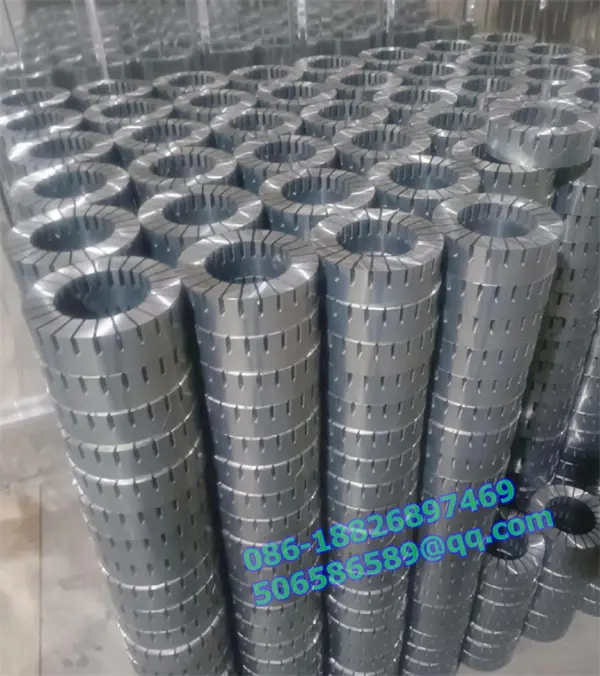

After punching is completed, the coiling device starts to work. It winds up the punched material by controlling the speed and direction of the disc motor. The take-up device usually consists of rollers or take-up shafts, which can take the material into rolls or rolls for subsequent processing or transportation.

4. Inspection and adjustment

During the stamping, punching and coiling process, it is necessary to regularly check and adjust the operating status of the equipment and the position of the punch. This ensures punching accuracy and consistency and avoids equipment failure or material damage.

5. Cycling operation

Stamping, punching and coiling machines can usually perform continuous cyclic operation to improve production efficiency. In each cycle, the steps of stamping, punching, and coiling materials are repeated until the required number of workpieces is completed or production requirements are met.

These steps can be adjusted and optimized based on the specific punching and punching coiler design and requirements. Through reasonable operation and control, the disc motor (axial flux motor) stamping and punching coiler can achieve efficient and precise stamping and punching operations and improve production efficiency.

Manufacturer of Disc Motor (Axial Magnetic Flux Motor) Stamping, Punching, and Coiling Machine

Are you looking for a reliable manufacturer of punching, punching, and coiling mechanisms for disc motors (axial flux motors)? YOUYOU is your best choice! We provide high-quality and high-performance disc motors (axial flux motors) for punching, punching, and coiling machines to meet various application requirements. We have advanced production equipment and a technical team, providing customized solutions to ensure product quality and reliability. By choosing YOUYOU, you will gain reliable partners to provide the best solution for disc motors (axial magnetic flux motors) stamping, punching, and coiling machines for your project. Please contact our sales team for more detailed information!